Fixing a Broken Frigidaire Dishwasher Dispenser

TL;DR

Our dishwasher broke and we modeled and 3D printed a part to fix it well before it could be delivered. Read the rest of the post to see how we did it and how it worked!

The story

We always have people asking us "What have you printed with your 3D printer?" And I usually find myself thinking really hard about something practical. We've printed simple parts before to fix or improve things but they've always been really easy things, simple models or something we've found online already modeled.

This week, Hester told me the Dishwasher dispenser had stopped working. Truthfully, I think I was told it was a problem for a couple of weeks, but this time I actually heard it. Taking a quick look at it, the door spring worked fine, but the door latch wasn't "springing" like it used to. At first I thought it might be a broken or weak spring.

The Fix

First we turned off the power to the dishwasher. PSA: Label your circuit breakers! After having Hester watch the dishwasher lights and pressing buttons while I flipped breakers for 5 minutes, we found the breaker!

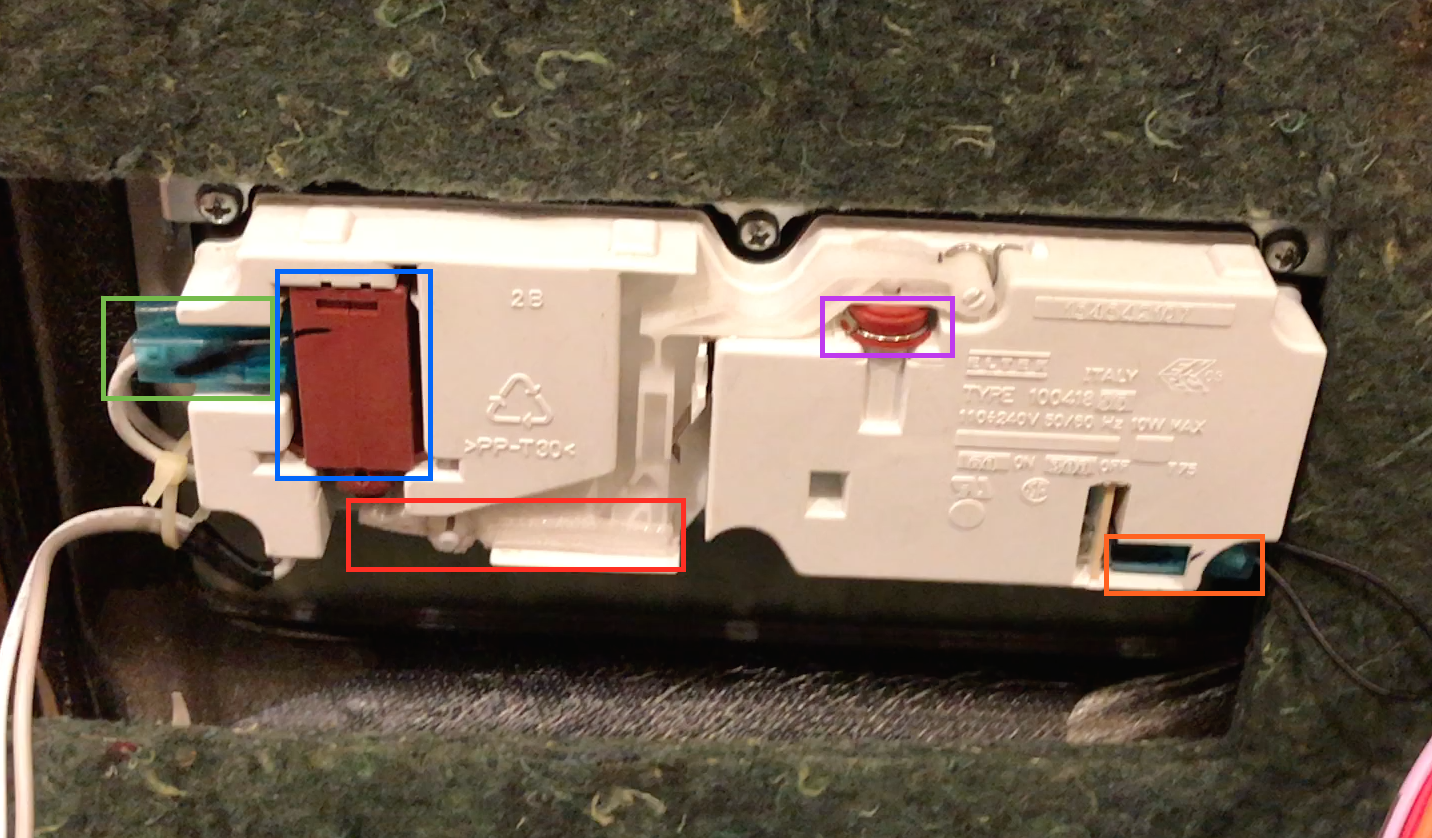

Getting the door apart was pretty easy, 12 T-15 screws and the front comes right off. I would recommend having something on the floor behind the door to hold the front up when all the screws are removed. Also remove the blue screws first, then the yellow and when removing the purple, put some pressure on the panel near those screws to prevent the door from springing up (all the weight is in the front of the door). Finally removing the red screws, the whole panel will want to slam back... It's not terribly powerful but if it catches you off guard some wires might get damaged. When all the screws are removed, pick both panels up as a unit and return to the closed position. There's enough slack in the wires that you can move the front to the side and get to the dispenser from the front side.

Take red screws out last, or you're going to have a bad time. Also note that Yellow and Purple are different sizes from the rest of the screws. Yellow are long and purple are medium, while blue and red are the same small size.

6 phillips screws and 4 wires and the dispenser comes out. Make note of the solenoid (blue box) wires on the left side (green box). The grey colored wire plugs in behind the white wire with the black mark on it. I believe the polarity matters here. The wires on the right side (orange box) go to the rinse aid level sensor, polarity probably doesn't matter here there is a black mark to indicate the front wire in the pair. The purple box is the rinse aid dispenser pump. Looking at the unit from the back, it seemed like the joint interface between the solenoid arm (red box) and the door latch was a bit sloppy.

Pulling the solenoid arm and latch out and testing from a better vantage point, you can see the amount of slop in the square section of the joint. It was clear that this was the cause of the door latch not springing back.

Let's see if we can find a replacement part...

Not as bad as I thought it would be for an entire assembly, but 2 days waiting and $30... I wondered if we could model and print a suitable replacement. Since it looked like I could have it ordered and shipped same day if I ordered within 5 hours, I gave myself 4 hours on the clock to print a replacement part, or face defeat and order it...

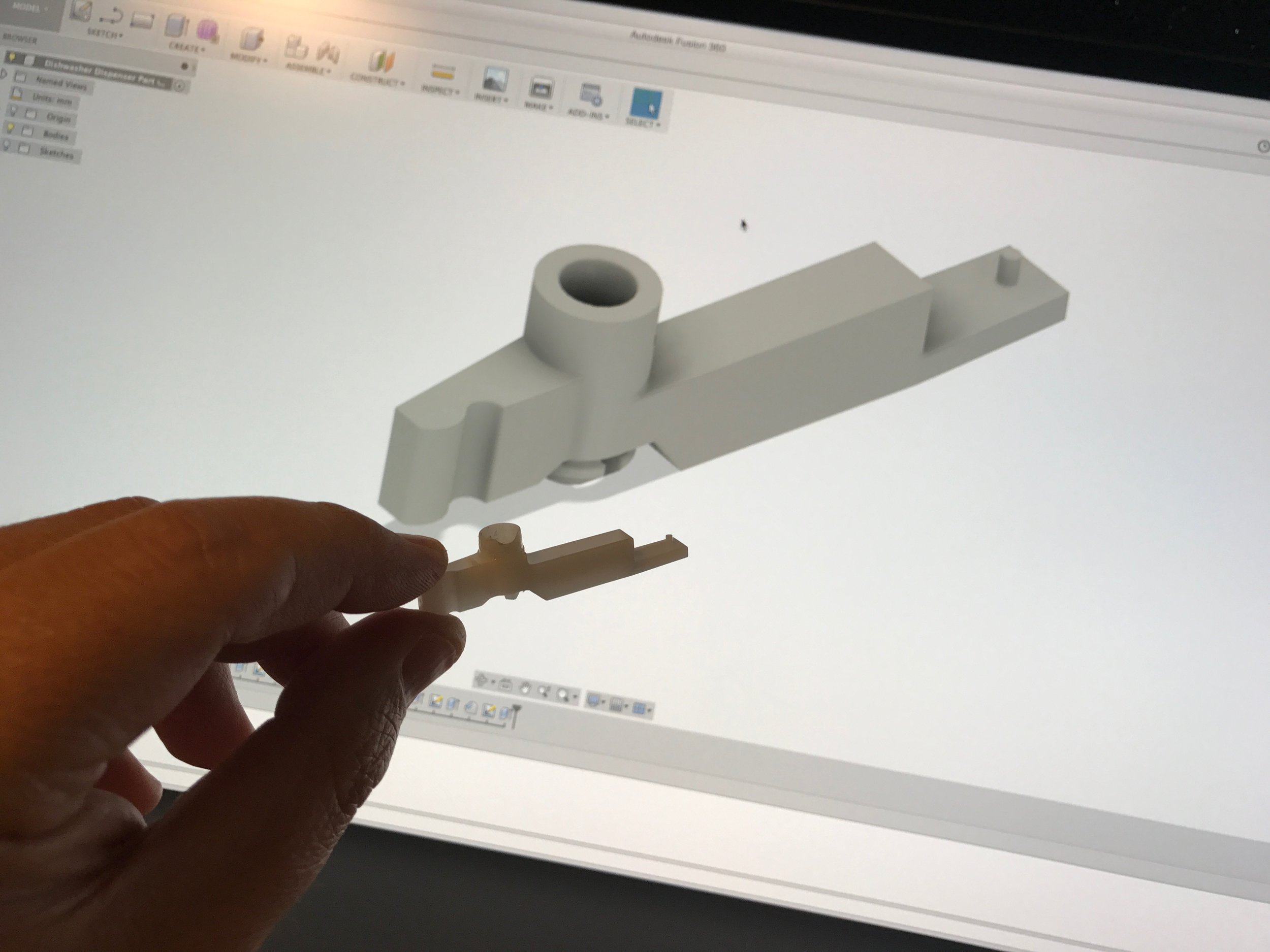

Measuring this thing was a challenge. There were a lot of curves and irregular features. I divided up the part and decided on a right angle to use as the source of truth for all of my measurements. I also had the door latch which I could reference for the internal measurements. The fit was made to be ultra tight in hopes this would last a little longer than the original.

The modeling turned out to be a fun exercise. I'm by no means an expert with Fusion 360 but I've been getting better. Normally I would obsess over chamfers, fillets, and smoothing things out, but this was functional and should do the job! It took me about 2 hours to model this. I learned a few tricks though, if I did it again it would go much faster.

Just a visual comparison, it looked right...but would it print right?

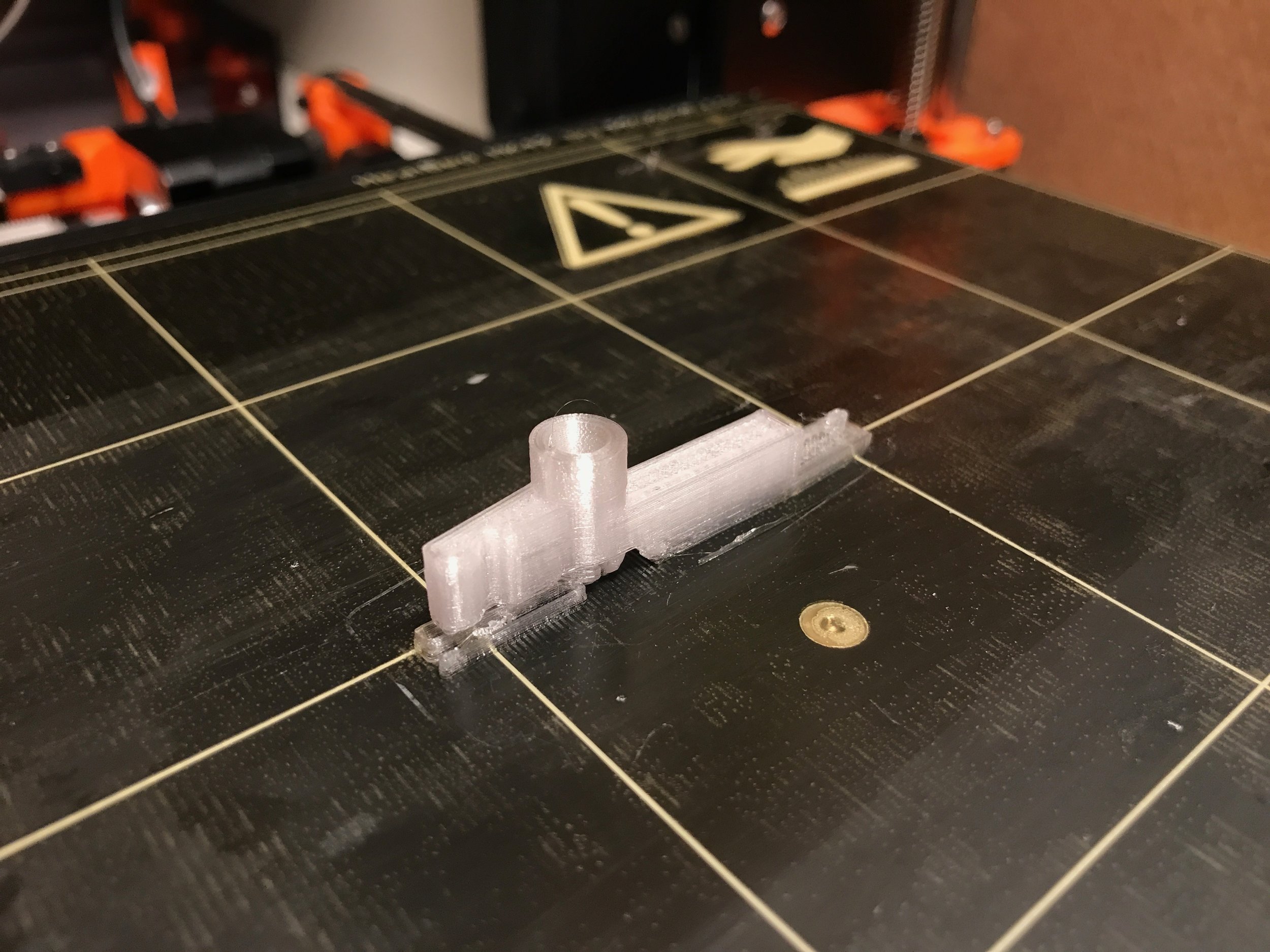

I exported the model as an STL from Fusion 360 and imported it into my slicer (turns a 3D model into G-code for the 3D Printer). Sliced it up with Simplify3D which reported the print time to be around 20 minutes, which isn't too bad.

If this had been something you could download from the manufacturer (instead of designing on your own) you could be back up and running in minutes! Now, the moment of truth!

We chose PETG as our filament for this print. PETG is very strong, has good layer adhesion, limited shrinkage, and high heat resistance. For replacement parts it's a pretty good choice.

So far so good... We printed this at 0.2MM layer heights/resolution and 20% infill, which is pretty standard. It's a utility print and doesn't need to look pretty, no point in extending the print time. The curves all came out very smooth, the whole part felt a little slippery, which should be good for how it contacts the rest of the unit.

Looks like a good match to me... But will it fit?

It fits quite well. It's hard to see here, but there's a spring wound around the shaft of the new part as well. Everything fit nicely, the door latch barrel was extremely tight, but that's what we wanted.

Larger view. The solenoid (red object on the left) pushes down on the arm. The dispenser arm handles two functions. It releases the lock on the door of the detergent dispenser at one point during the wash cycle, and then an additional stroke dispenses rinse aid (red object in the top middle of the unit) on the rinse portion of the wash cycle. The only thing left is to test it! Doing a static test on the workbench showed that it should work. I didn't want to hook 110VAC up to the solenoid because...well...I didn't want to, okay!?

The Result

Imagine our surprise when we opened the dishwasher door after a run and the door was actually open! And the dishes were clean! Yay! For reference, the part number for the full replacement module is: Frigidaire 5304507354.

Epilogue

This was fun, but also something that resolved a problem faster than buying a part could have. It's also possible that the part we created is better than the original, only time will tell.

I imagine the day will come in the not too distant future where you could download the STL (3D Printer file) from an appliance manufacturer to print a replacement part, or at least an authorized repair station could.

Once 3D printing gets to a point where it is extremely reliable, reproducible, and accurate to the mass market, this could be a possibility.

Of course there are those manufacturers who design for planned obsolescence, and in those cases it may still be a community driven effort. In a few years 3D Printing will be at the point where stuff will "just work" there are already production printers now where the operator does little to the printer itself, though the prices for those production printers are still into the thousands.

What We Used

Printer: Prusa i3 MK2

Software: Autodesk Fusion 360 (to model the part), Simplify 3D (to slice the part)

Printer Filament: Taulman Tech-G PETG filament

Our modeled part on Thingiverse (print your own): https://www.thingiverse.com/thing:2443056

Fusion 360 Model: http://a360.co/2DNq1wa