3D-Printing a Violin? Part 2

It's done

But, let's take a few steps back here. I deviated from the original instructions in just one place. They recommend printing at 0.3mm resolution (which is more efficient) however I've usually print at 0.2mm or lower and I've not printed anything substantial at lower resolution (higher number) and didn't want to risk it. The result was the print probably took 2x a long, but since I had to go away for work this week the print time didn't matter.

The neck

The first thing we printed was the neck, and this was to be printed at 0.1mm resolution because it needed to be a bit smoother than everything else. I considered printing this at 0.05mm resolution but decided against it since it would have taken a ridiculous amount of time to print and honestly I don't think it would have mattered much.

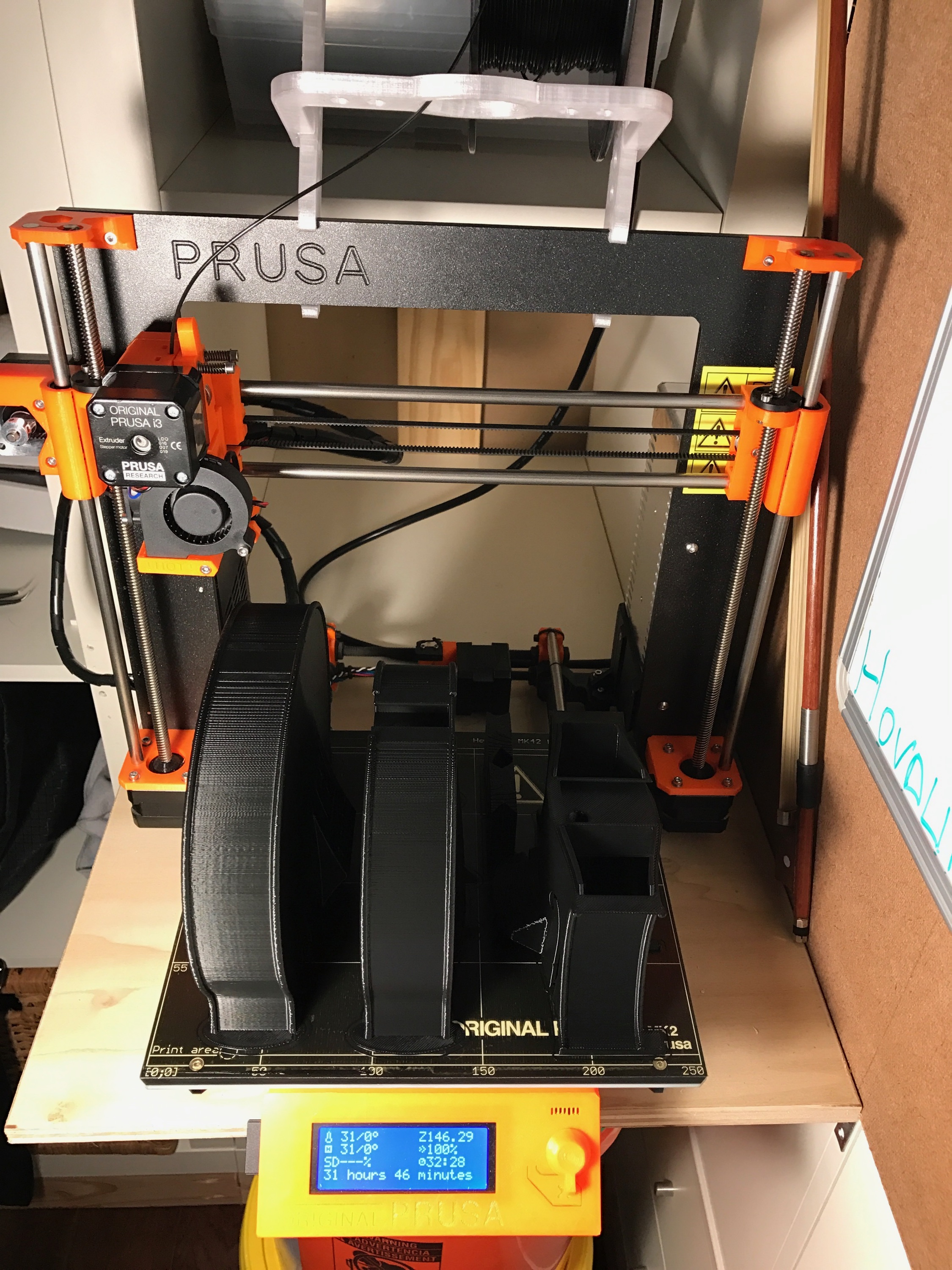

It came out just fine and took our printer 18 hours, double Hova Lab's estimates. This is not as much a comment on the Prusa i3 Mk2 as it is my conservative settings. I'm not big into printing things fast, I'm more about precision. I tend to 1/2 my speeds over what most people do. I'm pretty sure I could have gotten away with cranking things up, but hey I don't have to sit there and watch and worry. :)

Everything else

With the neck out of the way I organized everything on the build plate in Simplify3D so I could print all the parts at once. As I did with my test print, I used different "Processes" for each part so I could use different perimeter settings and batch everything out. I did this mostly because I had to travel this week and wanted to get as much done as possible so we could start the build when I got home.

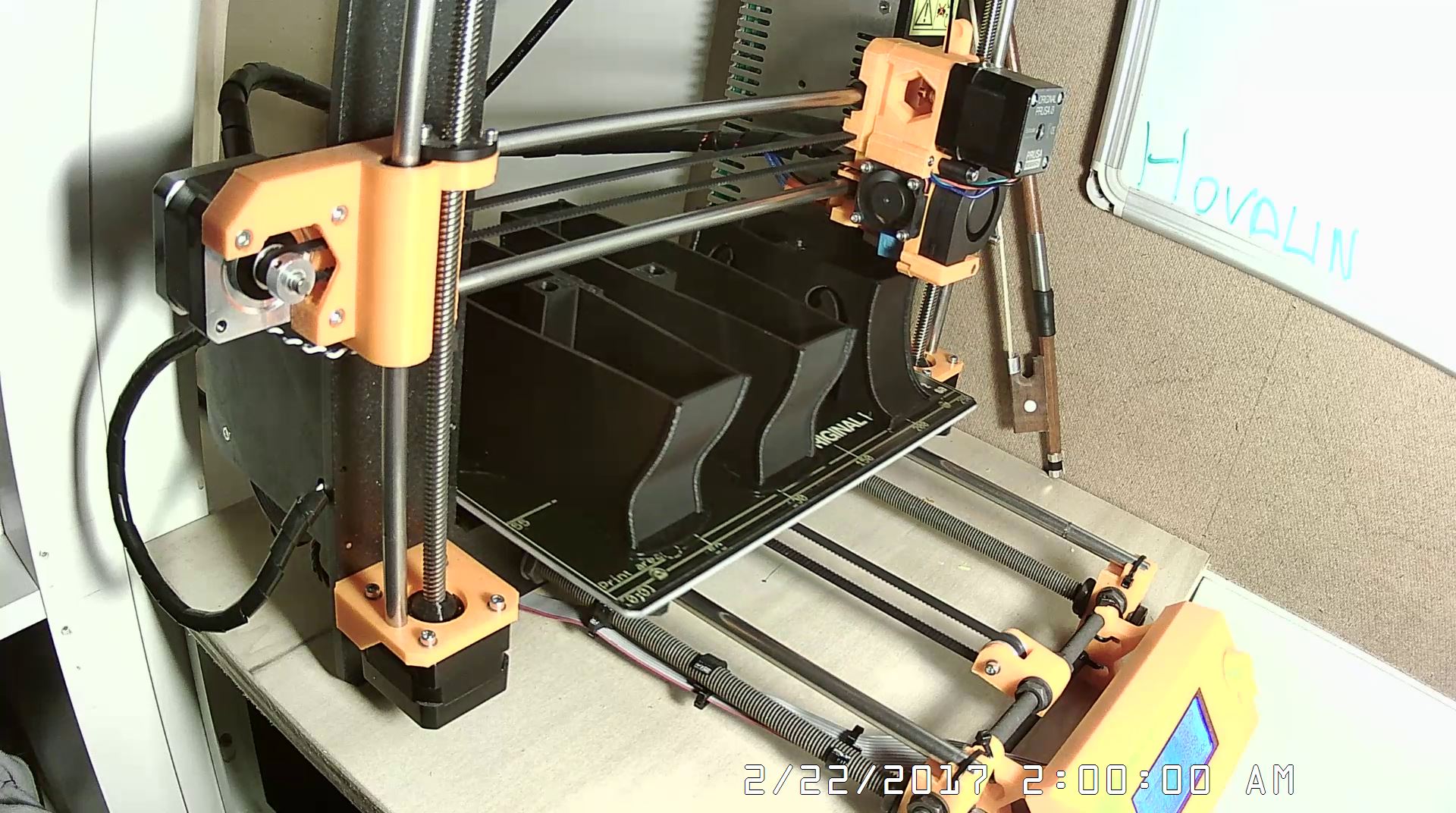

It was expected to take a good while. I rigged up a spare web cam I had and checked the progress while I was traveling. It was fun to watch but I fully expected to check in on the print at one point and see a giant lump of mutilated filament on the bed. However my fears were put to rest after 31 hours 46 minutes when Hester sent me the photo below. I couldn't believe it! The longest print we've ever done went off without a hitch!

We had Blue Iris (our Security Camera DVR software) take a snapshot every 30 seconds and save it to a folder...and totally intended to make a cool time-lapse compilation but I forgot that I had set a storage quota and then forgot to turn off the recording, so what we have is about 72 hours of a still image of the finished print... Oh well, next time!

Assembly

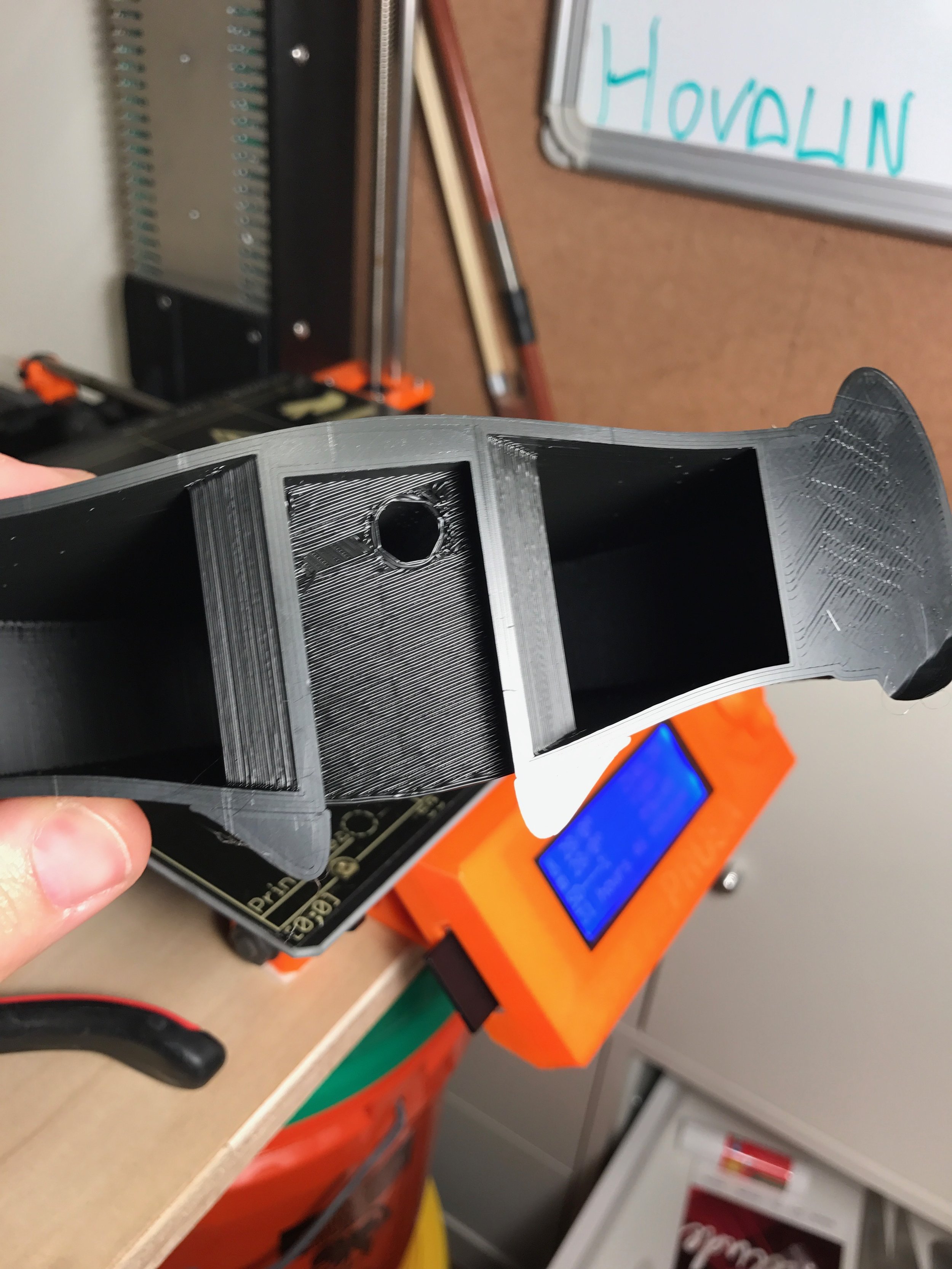

Hova Labs build instructions were perfect, I wouldn't change a thing. Everything went together perfectly, the built-in supports removed with little to no force and we didn't have to do any modification or fitting apart from what was in their instructions.

Supports before

Supports after

Stringing it up

I've never done this before, and I just decided to wing it. I noticed there was a color code to the strings and I just copied the photos from Hova Labs. I wasn't quite sure how to "finish off" the bit around the tuner, so I just ran the string back through the hole twice and gave it a good tug, cut off the excess, and turned the tuner to get it somewhat tight. Seemed to work just fine, but time will tell if it holds a tune.

Tuning

We have an app on my phone we've used to tune Penelope's toy guitar, and turns out it has a mode for tuning a violin as well. We started with G then moved on to D,A,E. Went back and then retuned each a couple of times as the act of tuning will pull and deflect the neck a little bit. We'll probably need to retune after a couple of days and some playing once everything settles in.

Playing

Well, it makes noise! Hester gives us a sample of her best elementary school violin action!

Thoughts

Well, it was a fun exercise. Is it practical to print your own violin? I guess it's not the worst idea in the world. You can certainly buy one cheaper on-line. The 3d printing option does give you the ability to customize a bit more and potentially make something better than you could buy it.

It was amazing to take someone else's design and print on a printer it wasn't designed or tested for. It really shows how practical this type of distribution can be. Please let us know what you think, and if you want to see more 3d printed projects like this!

- Hester, Bill, and Penelope.

P.S. if you haven't checked out part one, check it out here.